Digital Printing Technology

Learning more about the history Direct to Garment Printing, the technology, and the companies that do the manufacturing, will help you sift through all the product options available today. Understanding where the product line has been and where it’s going will help you properly frame all the editorial comments you may find during your research.

After all, the Direct to Garment Printer industry has come a long way since it first came to be in the United States in late 2004 to early 2005. While you read below and examine the timeline image, think about all the other changes that have taken place since then. Here are a few reminders for reference:

Look Back at 2005

- Your cell phone was likely either a Nokia, Motorola, Sony or Blackberry (iPhones were not released until 2007)

- You listened to music on a portable cassette tape or CD player or one of those new "high tech" MP3 players with your wired earphones (iPods were just beginning to take hold)

- There were payphones everywhere (you know, you carried a pocket full of coins to make "local" calls!)

- You were probably "IM" ing on AOL

- There was no Amazon Kindle (launched in 2007) and Amazon Prime was just starting

- Lenovo ThinkPad X41 was the most notable computer of the day - $2,249!

- 90%+ of homes in America had a landline phone

The Beginnings of DTG

(Direct to garment printing launches at 2004 SGIA Minneapolis)

Until late 2004 the only real option you had if you wanted to enter the printed shirt business was screen printing. Screen printing is a largely manual process that involves dragging ink across a porous "screen" with an image on it, transferring that ink to the garment below. But like the transition from large commercial printing and publishing companies to desktop publishing some decades earlier, the custom t-shirt business was ready for a digital revolution.

The direct to garment printer industry in the United States was launched in late 2004 at the SGIA show in Minneapolis. At that show, both Kornit & U.S. Screen showed direct to garment printers for the first time, joining Mimaki in the direct to garment printer marketplace. Mimaki's first printer was the GP-604 (and GP-604D – with discharge liquid used for printing darks), U.S. Screen's first machine was called the Fast T-Jet (manufactured by Mastermind in Japan) and Kornit entered the market with the Storm.

These three early printers were vastly different. The Kornit was a large, industrial printer (over $200,000 price tag) that was capable of printing both light and dark garments. It was the only one of the three with white ink.

The Mimaki GP-604 was a C,M,Y,K only machine, but the GP-604D incorporated a secondary head that jetted discharge fluid onto the garment to “release” the dyes in the shirt. White ink was not needed – It was a great concept, but to get good results, you needed to use discharge-ready garments, which were pricier than other garments and very limited in styles and colors. Also, the discharge fluid was very harsh on the print heads. The GP-604 started at around $30,000. The Fast T-Jet was a 7-color machine (C,M,Y,K,Lc,Lm,Lk) – with no ability to print darks. The price point on the Fast T-Jet was $10,000.

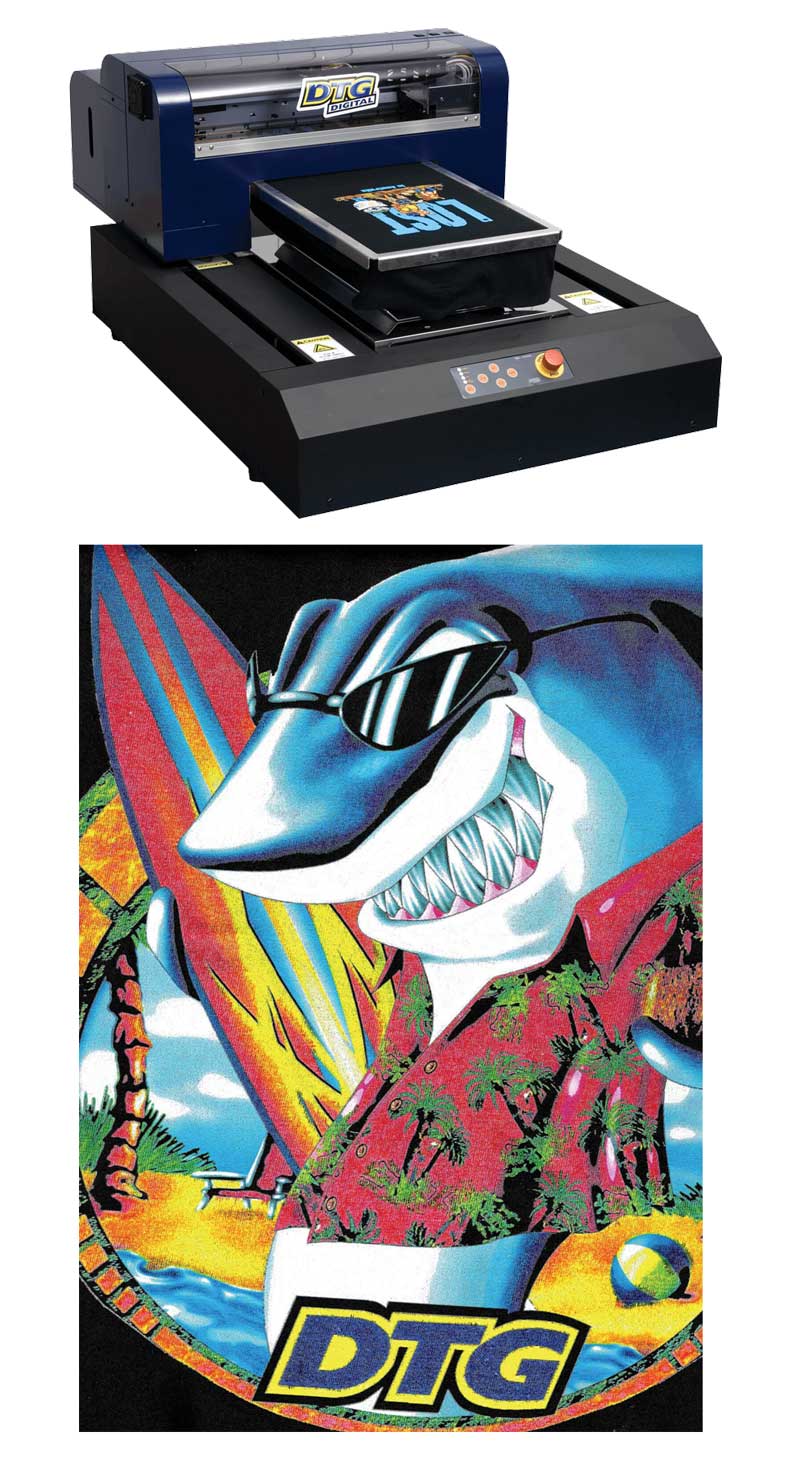

Early Model Brother DTG Printer and DTG Brand Hits the Market

Early 2005 brought the first large traditional printer company into the marketplace as Brother introduced their GT-541 – also a light shirt-only printing solution – at the Atlantic City ISS show. First machines started hitting end-user shops near the end of the year.

October 2005 saw the introduction of the first DTG brand direct to garment printer – the Kiosk – at the ITMA Asia show in Singapore. The Kiosk offered some significant direct-to-garment specific enhancements over the other models in the price range. It had automated head cleanings, a valve system to shut off specific ink channels and more user-friendly ink chip resetting.

ColDesi formally rolled out the Kiosk in America at the 2006 Atlantic City ISS show.

The DTG Brand Takes A Unique Approach

Early Direct to Dark Garment Printing – White Ink Revolution

Up until the end of 2005, all of the t-shirt printing machines on the market (except for the $200,000+ Kornit) could only print on light garments because white ink did not yet exist for the lower viscosity printheads used by most of these machines.

A radical change to the market came at the end of 2005 when U.S. Screen released white ink (developed by DuPont) for their Fast T-Jet printers. Although the pretreatment process was VERY complex, end-users were finally able to print on dark garments. White ink allowed for an underbase to be laid down that would then be printed on by the full-color ink set – dark shirts were now "fair game" for the early adopters of the technology!

U.S. Screen sales of printers exploded, and the direct to garment marketplace would never be the same again.

A year later, the U.S. Screen exclusive with DuPont on white ink expired, and other vendors, like DTG Digital were given the opportunity to add white ink to their printers. A year of in-the-field experience made it evident that changes were needed to manage the white ink which has radically different properties than the color inks (inorganic pigment vs. organic pigment).

The push for white ink consistency led the DTG brand direct-to-garment printer group to develop new ideas on managing the white ink.

The earliest example came on the DTG HM1. The white ink was contained in a single, large bottle that had a magnetic stir pill in it the stirred the white ink periodically to minimize settling. Not long afterward the HM1 was upgraded to the HM1-C, which replaced the stir pill with a peristaltic white ink circulation system (thus the “C”).

Nearly 15 years later there are still many people that are using the DTG Kiosk and the HM1/HM1-C. But, the current generations are much more reliable, use much less ink, and no longer have the white ink issues that plagued the industry early on.

The DTG exclusive White Ink Management System was born – known by its acronym – WIMS. This invention helped to greatly reduce the maintenance issues associated with the settling of white ink as well as helping to deliver the large volume of white ink needed for good coverage to the print head on a consistent basis.

The video below describes the modern version of that first WIMS system:

Next-generation Direct to Garment Printers

In early 2009 the DTG Viper entered the market and set new standards for productivity. With its unique belt-fed system a shop could now setup a "print through" operation. This format was more conducive to efficiency, especially in shops where space was not a major concern. With the DTG-designed 4-2-1 platen system a user was also able to produce multiple garments at one time without having to dedicate a huge amount of space to oversized printers.

The Viper also marked another step in the evolution of the DTG line; Not only was the WIMS system enhanced to now incorporate a stirrer in the white ink bottle as well as circulating the ink through the system – but the color ink system was now also pressurized to eliminate issues of ink flow during periods of heavy production.

Just for comparison, in 2009 Windows 7 was introduced, the Smart Thermostat was invented and the iPhone App Store turned 1 Year old

DTG became MORE than just a passing fad.

Until this point all of the DTG brand direct to garment printers had been based on core Epson printers (in fact, most of the direct to garment printers on the market were as well).

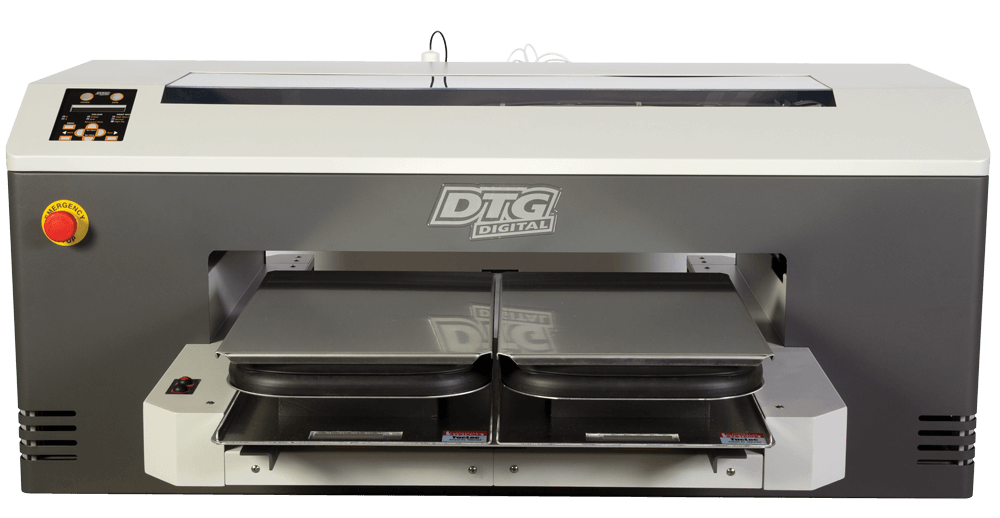

Following the international release of the DTG M2 in Hamburg at FESPA in late May of 2011 ColDesi unveiled the DTG M2 in September at the Fort Worth ISS Show. The M2 became the first DTG brand printer not to start its life as an Epson page printer. The M2 was a joint effort between DTG Digital and Mutoh, manufacturer of large format printers. Gone were the non-direct to garment errors & messages associated with re-purposed printers, no more ink chips & waste counters to reset.

Clever engineering greatly increased the serviceability of the machine and a two across platen system nearly doubled productivity and, with the dual platen topper, gave the largest print area in the direct to garment marketplace at 16.5″ x 24″.

DTG M2 Direct to Garment Printer

The M2 represented a big jump in both technology and reliability for the DTG and t-shirt printing marketplace. Large screen printers & fulfillment houses were now starting to incorporate DTG printing into their business. The largest production houses were using over 30 M2s to churn out vast numbers of shirts every day.

To remind you of what was going on in 2011 – the world lost Apple founder Steve Jobs but not before he launched the iPad 2 in March, Amazon entered the tablet market and sold 4 million+ Kindle Fire tablets and Netflix was struggling with transitioning from DVD rentals to online streaming of movies.

Pretreatment Machines Enter the Market

DTG Pretreat-R Gen II

With white ink becoming less of a hassle from the printer standpoint, thanks to the WIMS system on the DTG printers, it was time to focus on consistent application of the pretreatment required to print white ink.

In 2010 ColDesi released the DTG Pretreat-R Gen II – a joint venture between Lawson and ColDesi. The machine was a big step forward and remained the standard for pretreatment machines until 2014 when ColDesi became the North American distributor for the Spider Mini pretreatment machine made by Korean manufacturer Printsystem.

Spider Mini

The Spider Mini was a step forward from the previous Pretreat-R Gen II in that it was entirely enclosed, meaning it could be closer to the printer than before and had a much smaller footprint.

Easy switchover between pretreatments also made it a more user-friendly solution. The Spider Mini remained the choice for DTG brand printer users and those using other brands who needed a consistent pretreatment solution.

PTM

In September 2019, ColDesi introduced the PTM – DTG Digital's first entry into the automatic pretreatment marketplace.

The PTM had a lot of the same advantages as the Spider Mini, but included an easier access swivel platen for loading and a special coating which significantly reduced the corrosion caused by the salt-heavy pretreatments used in DTG printing.

Legacy DTG Brands Unite in Tampa

While ColDesi and DTG Digital were building their legacy in the direct to garment world, another player was doing much the same – and only miles away for ColDesi’s corporate offices in Tampa.

Mark Mombourquette and Brett Weibel of Belquette entered the direct to garment marketplace with their Flexi-Jet in February of 2006 at the ISS show in Orlando. The Flexi-Jet was an innovative machine that remained a significant player in the marketplace for a number of years.

In October 2008 the next generation of Belquette direct to garment printer launched – the MOD1. Another Epson-based machine with a tremendous amount of aftermarket engineering that set a standard for converted machines that was never really rivaled. Even the largest of on-demand direct to garment printing businesses took notice, purchasing hundreds of these machines for their operations.

At the 2008 SGIA show, Bequette debuted their Edge pretreatment machine that controlled the application of the pretreatment to an area very close to the shape of the design to be printed – technology.

That would be improved on and incorporated into the 2020 SGIA product of the year – the PTM One Step (more about that shortly!). Finally, in 2014 Belquette rolled out their ground-up built Genesis machine that incorporated a number of advantages over previous models of direct to garment printers.

ColDesi and DTG… and Belquette

Over the history of direct to garment printing and the custom t-shirt business, the DTG Brand has demonstrated its ability to innovate at the right pace, ensuring service and support are there to back up new technology.

More than 30% of ColDesi’s business are repeat customers, which is practically unheard of in the industry. By focusing on a total customer experience at a great price, the ColDesi brand became a household name among industry insiders.

Even embroidery professionals were buying DTG Printers, while custom t-shirt shops were expanding into rhinestone transfer machines. Even traditional Screen printers were adding direct to garment equipment for their short runs.

In March of 2018, Belquette and ColDesi announced that they were joining forces. The innovations of the Belquette crew coupled with the sales, support, and marketing strengths of ColDesi are proving to be a juggernaut in the direct to garment marketplace. Let’s look at the list of accomplishments from this partnership that have transpired in a few short years.

DTG G4 Flagship Printer With Vaccum Platten Makes its Debut

Things got moving quickly as the Belquette team, and ColDesi's DTG team, and engineering from DTG Digital got to work on finalizing the next generation of DTG brand printer – the DTG G4.

The G4 was formally released in the United States in November 2019 and incorporated the soon-to-be patented vacuum platen (patent issued in June 2020) and the new, improved Kodak ink set that was the culmination of a lot of work by all three entities and the chemists at Kodak. Quicker cure times and better colors were two of the main benefits of the new ink set.

OneStep Pretreatment

But things did not stop there; in October, the OneStep Pretreatment and Curing system won the Printing United Product of the Year award for innovation in the DTG-Pre-press category. Using technology gained from the Belquette Edge to target pretreatment and brand new technology allowing for targeted curing that saves time and energy. The One-Step is truly the leader into the next generation of pre and post-treatment solutions.

And things are just getting started! New generations of machines and accessories ranging from pre and post-treatment to add-ons to existing systems are on the horizon.

Learn why today by contacting ColDesi! or learn more about DTG Printers at www.dtgprintermachine.com